Top-Rated Hydraulic Hose Connectors for Long-Term Durability

In high-pressure systems where reliability is essential, Hydraulic hose connectors play a direct role in determining how well equipment performs over time. At Hebei Minglai Pipe Fitting, durability is more than a feature—it’s a requirement. Whether you’re running construction machinery, manufacturing equipment, or agricultural systems, choosing top-rated Hydraulic hose connectors ensures long-lasting performance, fewer breakdowns, and consistent operational safety. Understanding what makes certain connectors superior can help you invest wisely and avoid costly system failures.

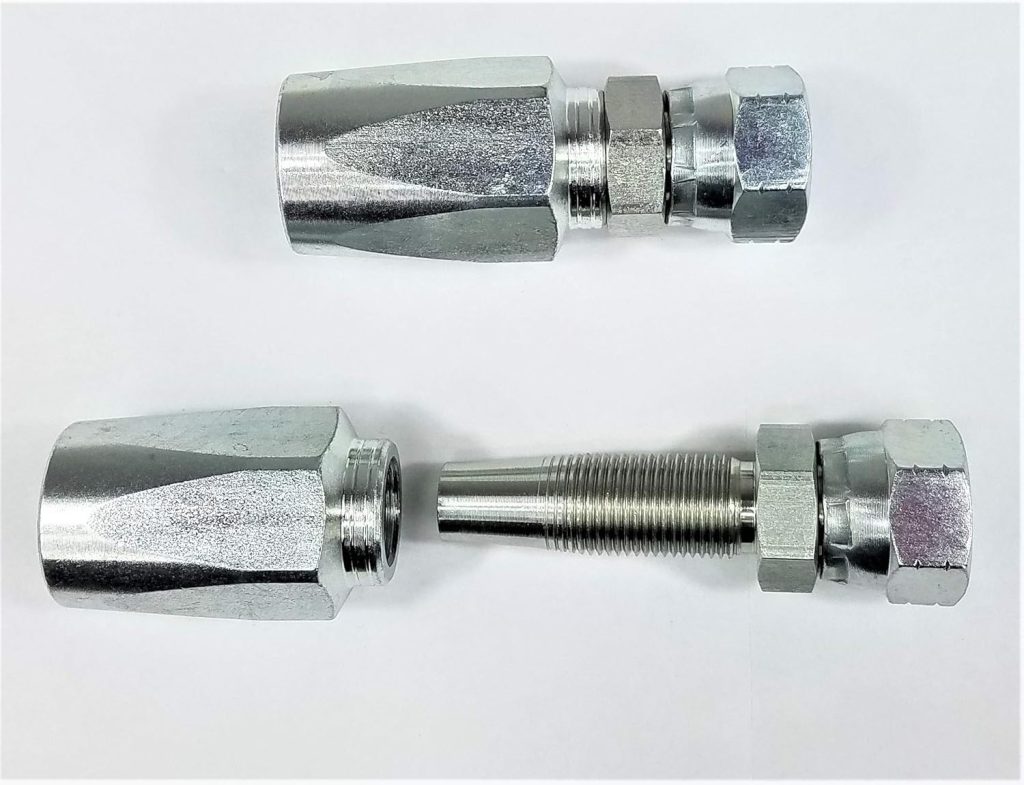

What Makes Hydraulic Hose Connectors Durable

Durability comes from a combination of material strength, engineering precision, and proper compatibility. High-quality Hydraulic hose connectors are built to withstand constant pressure cycles, vibration, and exposure to demanding environments.

Superior Material Strength

Top-rated Hydraulic hose connectors are often manufactured from stainless steel, carbon steel, or specially alloyed metals that resist corrosion, cracking, and fatigue. This ensures long-term durability in both indoor and outdoor applications.

Enhanced Sealing Technology

Advanced sealing mechanisms help premium Hydraulic hose connectors maintain leak-free operation even under fluctuating temperatures and extreme pressure spikes.

Why Long-Term Durability Matters

When connectors fail prematurely, the entire hydraulic system is at risk. Durable Hydraulic hose connectors reduce downtime, lower maintenance expenses, and protect critical components such as pumps, valves, and cylinders.

Lower Replacement Frequency

Since high-quality Hydraulic hose connectors last longer, they reduce the frequency of repairs and replacements, saving both labor and material costs.

Improved System Efficiency

Reliable sealing and stable pressure contribute to smoother system operation. Top-grade Hydraulic hose connectors help maintain consistent pressure levels, preventing overworking of hydraulic pumps.

Features of Top-Rated Hydraulic Hose Connectors

Certain design elements distinguish top-tier connectors from standard options.

Precision Machined Threads

Well-crafted Hydraulic hose connectors ensure perfect threading, preventing leaks, misalignment, and connection failures.

Corrosion-Resistant Coatings

Exposure to chemicals, moisture, and abrasive contaminants can degrade components. High-quality Hydraulic hose connectors use advanced plating or protective coatings to extend service life.

Vibration Resistance

In machinery that experiences heavy movement, durable Hydraulic hose connectors maintain stability without loosening or deforming.

Industries That Benefit from Top-Rated Connectors

Different industries rely heavily on strong, long-lasting connectors to maintain safe and efficient operations.

Construction and Earthmoving

Equipment like excavators and loaders must withstand extreme pressure surges. Premium Hydraulic hose connectors help prevent downtime on demanding job sites.

Manufacturing and Automation

Precision-driven systems depend on stable pressure. Long-lasting Hydraulic hose connectors ensure smooth, uninterrupted production cycles.

Agriculture and Forestry

Outdoor equipment faces harsh weather and debris exposure. Durable Hydraulic hose connectors protect systems from unexpected failures during field operations.

How to Identify High-Quality Connectors

Choosing the right components involves inspecting several key features.

Compatibility and Fit

Properly matched Hydraulic hose connectors prevent system strain and ensure reliable sealing.

Pressure and Temperature Ratings

Top-grade Hydraulic hose connectors are thoroughly tested to meet industry-rated performance standards.

Manufacturer Reputation

Companies known for precision and strict quality control—such as Hebei Minglai Pipe Fitting—deliver dependable Hydraulic hose connectors designed for long-term use.

Maintenance Tips to Extend Durability

Even the best components last longer with proper maintenance.

Regular Inspections

Check your Hydraulic hose connectors for signs of wear, corrosion, or thread damage.

Proper Installation

Ensuring correct torque and alignment helps prevent premature stress on Hydraulic hose connectors.

Conclusion

Long-term durability in a hydraulic system relies heavily on the quality and engineering of its fittings. By choosing components made from strong materials, designed with precision, and tested under real-world conditions, you ensure consistent performance and reduced maintenance costs. Top-rated connectors from Hebei Minglai Pipe Fitting offer the reliability needed to keep your machinery running smoothly, safely, and efficiently for years to come.