Understanding Injection Robots: Basics and Benefits

In the fast-evolving landscape of industrial manufacturing, Injection Robot technology stands out as a pivotal innovation. These sophisticated machines are designed to streamline production processes, enhance precision, and drastically improve operational efficiency. As manufacturers strive to meet the growing demand for high-quality products, the integration of injection robots is not just advantageous; it’s becoming essential. This article delves into the fundamentals of injection robots, their features, and the manifold benefits they offer to industries worldwide.

What is an Injection Robot?

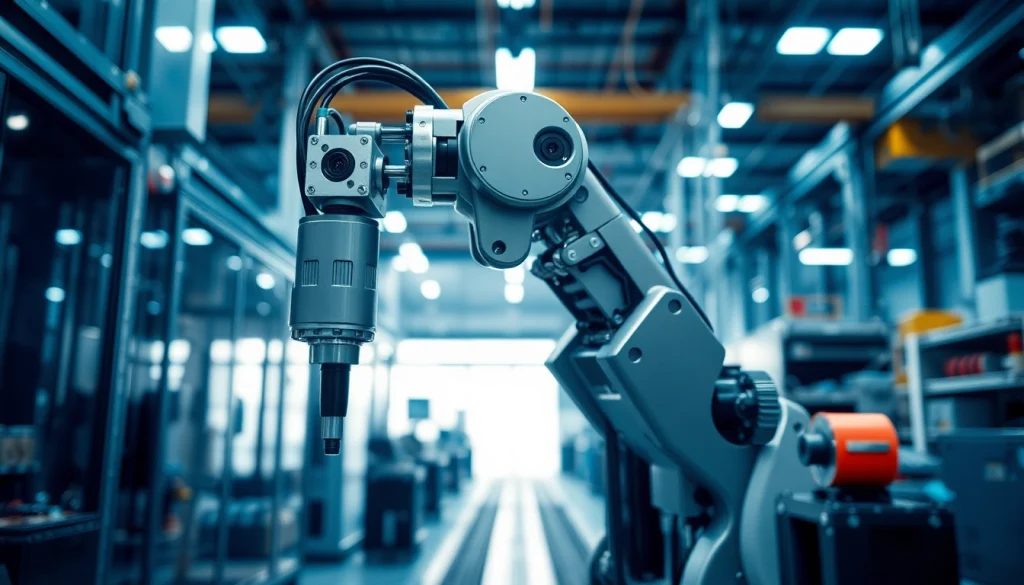

An injection robot is a robotic system that automates the tasks associated with injection molding processes. This technology is primarily used in manufacturing environments to improve efficiency by performing repetitive actions like handling, sorting, and packing molded parts. Injection robots can take many forms, including articulated arms and Cartesian systems, each designed to cater to specific manufacturing needs.

Key Features of Modern Injection Robots

- Precision: Modern injection robots are equipped with advanced sensors and software that ensure a high degree of accuracy in handling components, resulting in reduced waste and improved quality of the final products.

- Speed: These robots operate at remarkable speeds, significantly reducing cycle times in production lines, which enhances overall productivity.

- Flexibility: Injection robots can be programmed for various tasks, making them versatile tools in a manufacturing setting, capable of adapting to different production requirements.

- Integration: They can seamlessly integrate with existing manufacturing systems, allowing for improved synchronization and workflow efficiency.

Benefits of Using Injection Robots in Manufacturing

The implementation of injection robots in manufacturing is associated with a wide range of benefits. Firstly, they contribute to operational efficiency by minimizing manual labor and reducing human error. This leads to lower operational costs in the long run. Secondly, injection robots facilitate greater scalability, allowing businesses to ramp up production as demand increases without compromising on quality.

Moreover, the use of robots enhances workplace safety by taking over dangerous tasks, thus reducing the risk of workplace injuries. In summary, integrating injection robots can transform traditional manufacturing processes into highly efficient and safer operations.

How Injection Robots Transform Industrial Production

Efficiency Improvements with Injection Robots

One of the most significant impacts of injection robots is the substantial improvement in efficiency. By automating repetitive tasks, these robots not only speed up the production process but also ensure a consistent output quality. This dual benefit leads to higher customer satisfaction and better reputation for manufacturers in a competitive market.

Cost-Effectiveness of Automated Systems

While the initial investment in injection robots may seem substantial, the long-term savings they offer are undeniable. Automated systems reduce labor costs, minimize waste, and enhance energy efficiency. As production scales up, the per-unit cost of each manufactured item decreases significantly due to the efficiencies achieved, providing a compelling argument for their widespread adoption.

Real-World Applications of Injection Robots in Manufacturing

Injection robots find applications across various industries, from automotive to consumer goods. For instance, in the automotive industry, these robots are used for the rapid assembly of components, improving the speed and precision of car manufacturing. Similarly, in the consumer goods sector, they assist in the molding and packaging of items like toys and electronics, demonstrating their versatility and widespread utility.

Choosing the Right Injection Robot for Your Needs

Factors to Consider When Selecting an Injection Robot

When selecting an injection robot, businesses should consider several factors, including the robot’s payload capacity, speed, flexibility, and the specific tasks it needs to perform. Evaluating the production volume and the complexity of the tasks will also guide the choice of robot model and configuration.

Comparing Different Types of Injection Robots

There are primarily two types of injection robots: hydraulic and electric. Hydraulic robots are known for their strength and are suitable for heavy-duty tasks, while electric robots offer better precision and are more energy-efficient. Understanding the specific requirements of the manufacturing process is key in making the right choice.

Vendor Considerations: Quality and Support

Selecting a reliable vendor for injection robots is crucial. The quality of the robots is paramount, along with the level of support offered. Maintenance services, training for operators, and warranty options should also be considered when making a purchasing decision.

Challenges and Solutions in Implementing Injection Robots

Common Misconceptions About Injection Robots

Despite their advantages, there are several misconceptions about injection robots. Many believe that implementing robotic systems will lead to job losses, whereas in reality, robots are there to augment human capabilities, allowing workers to focus on more complex tasks that require critical thinking and human insight.

Overcoming Integration Challenges in Manufacturing Environments

The integration of injection robots into existing production lines can pose challenges, particularly in terms of compatibility with current systems. However, with proper planning and expert consultation, these challenges can be addressed. Engaging with experienced vendors during the integration process can greatly ease the transition.

Future-Proofing Your Investment in Injection Robot Technology

Investing in injection robots is not just about immediate gains; it’s also about preparing for the future of manufacturing. Businesses should look for flexible robots that can adapt to changes in production demands, scalable solutions that can grow with the company, and those that come with regular software updates to enhance functionality.

Future Trends in Injection Robot Technology for 2025

Emerging Technologies Impacting Injection Robotics

The future of injection robotics is set to be shaped by several emerging technologies, including artificial intelligence and the Internet of Things (IoT). These technologies will further enhance the capabilities of injection robots, enabling them to learn from their operations and optimize performance automatically.

Predicted Developments in Automation for Manufacturing

As automation continues to evolve, we can expect injection robots to incorporate more advanced functionalities such as predictive maintenance, real-time analytics, and enhanced communication capabilities with other machinery in the production line. This will lead to smoother operations and increased overall efficiency.

Preparing for the Next Generation of Injection Robots

Manufacturers looking to stay ahead of the curve should invest in training their workforce on emerging robotic technologies and consider partnerships with tech companies that specialize in robotics. Emphasizing continuous learning and adaptability will be crucial as injection robot technology advances towards more sophisticated, intelligent systems.