Understanding Mobile Hydraulic Services

Mobile hydraulic services play a crucial role in various industries by providing on-site support and maintenance for hydraulic systems. These services are particularly important in sectors such as construction, agriculture, and manufacturing, where downtime can lead to significant financial losses. Companies specializing in mobile hydraulic services offer quick responses to equipment failures, ensuring that machinery remains operational and efficient.

What Are Mobile Hydraulic Services?

Mobile hydraulic services refer to the on-demand provision of maintenance, repair, and troubleshooting for hydraulic systems used in various machinery. These services are typically performed by skilled technicians equipped to handle hydraulic systems directly at the job site. By providing such services, companies help ensure minimal downtime and a quick turnaround for equipment repairs.

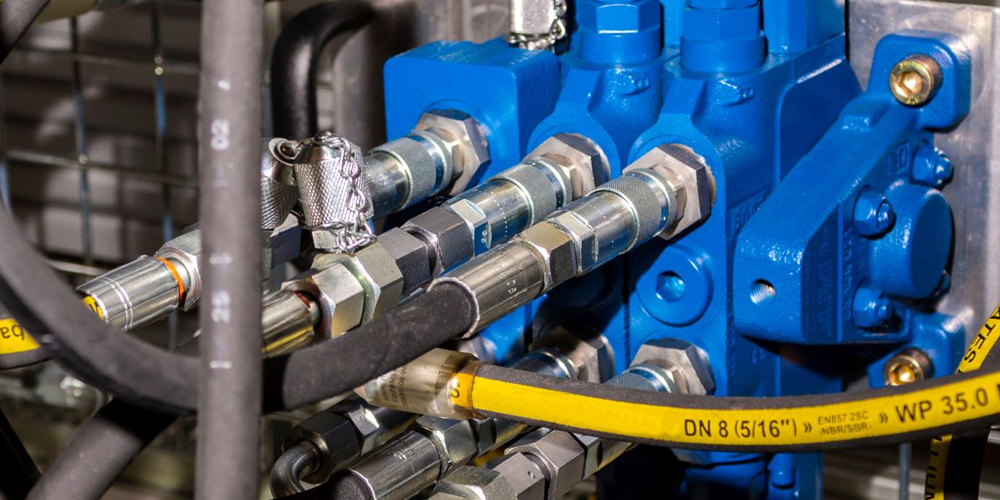

Key Components of Hydraulic Systems

A comprehensive understanding of hydraulic systems is essential for effective maintenance and repair. Some of the key components include:

- Pumps: Generate pressure to move fluid through the system.

- Actuators: Convert hydraulic energy back into motion.

- Valves: Control the flow and direction of hydraulic fluid.

- Hydraulic fluid: Transmits energy throughout the system and lubricates components.

- Reservoirs: Store hydraulic fluid, allowing for system expansion and fluid replacement.

These components work together to create a powerful system capable of moving heavy loads and performing various tasks, making regular maintenance vital to their efficiency and longevity.

Importance of Maintenance in Mobile Hydraulic Services

Regular maintenance is key to enhancing the performance and lifespan of hydraulic systems. It involves periodic inspections, cleaning, fluid changes, and component replacements. Such proactive measures can prevent major breakdowns, decrease repair costs, and improve overall system performance. Mobile hydraulic services are indispensable for ensuring this maintenance is accessible wherever the equipment operates.

Typical Applications of Mobile Hydraulic Services

Heavy Machinery and Construction

Mobile hydraulic services are prevalent in the heavy machinery and construction sectors, where machines like excavators, cranes, and forklifts rely heavily on hydraulic systems. These services ensure that critical machinery experiences minimal downtime due to hydraulic failures, which can be caused by leaks or system malfunctions. By having mobile technicians on hand, construction projects can maintain their schedules and avoid costly delays.

Agricultural Machinery Support

In agriculture, equipment such as tractors, harvesters, and irrigation systems often utilize hydraulic functionality. Mobile hydraulic services provide farmers with immediate assistance in the field, addressing any issues that arise. This on-site support helps in maintaining productivity during peak seasons, where every hour counts. Effective maintenance and quick repairs can lead to better crop yield and operational efficiency.

Industrial Machinery Applications

Industries such as manufacturing, mining, and logistics leverage mobile hydraulic services to maintain machinery like conveyor systems, loaders, and presses. These systems require constant upkeep due to their high operational demands. Mobile service providers can optimize machine performance by identifying common issues, preventing unexpected failures, and ensuring compliance with safety regulations.

Common Issues Addressed by Mobile Hydraulic Services

Leaks and Fluid Loss

Leaks are one of the most common issues faced by hydraulic systems. They can lead to fluid loss, reduced efficiency, and environmental hazards. Mobile hydraulic services can quickly detect and repair leaks, ensuring that equipment maintains optimal performance and safety levels. Regular checks and prompt repairs are essential to avoid the cascading effects of fluid loss.

System Failures and Troubleshooting

System failures can occur without warning and halt operations. Mobile hydraulic technicians possess the expertise to troubleshoot such failures efficiently. They utilize diagnostic tools to identify issues, whether related to pumps, valves, or fluid contamination. Their ability to provide immediate repairs minimizes downtime and keeps operational costs under control.

Improving Equipment Lifespan

Mobile hydraulic services play a vital role in enhancing the lifespan of hydraulic equipment. Regular maintenance not only identifies potential issues before they escalate but also helps in keeping fluid clean and components well-lubricated. This preventative approach ensures that machinery can operate smoothly and reduces the likelihood of future repairs, ultimately extending service life.

Best Practices for Utilizing Mobile Hydraulic Services

Choosing the Right Service Provider

Selecting a reputable mobile hydraulic service provider is crucial for ensuring quality service. Look for companies with proven track records, qualified technicians, and comprehensive service offerings. Customer reviews and testimonials can also provide insight into their reliability and expertise. The right provider will be equipped to handle a wide range of hydraulic issues and offer personalized service plans.

Preventative Maintenance Strategies

Implementing a robust preventative maintenance strategy is essential. This includes regular inspections, fluid analysis, and proactive replacement of worn components. Scheduling routine maintenance can catch problems before they develop into costly repairs, thereby enhancing machine efficiency. Partnering with mobile hydraulic services can help in setting up a tailored maintenance schedule that fits operational needs.

Timely Response and Availability

One of the key advantages of mobile hydraulic services is their accessibility. Timeliness in addressing hydraulic issues can significantly impact operations. Ensuring that the service provider has responsive customer support and a dependable team on call can prevent prolonged downtimes. It’s essential that businesses prioritize working with services that have a strong commitment to rapid response times.

Future Trends in Mobile Hydraulic Services

Technological Advancements

The future of mobile hydraulic services is heavily influenced by technological advancements. Innovations such as IoT (Internet of Things) sensors can provide real-time monitoring of hydraulic systems, allowing for data-driven maintenance decisions. This technology can lead to predictive analysis, wherein companies can forecast potential failures based on usage patterns and system performance.

Sustainability in Hydraulic Solutions

As industries advance toward more sustainable practices, mobile hydraulic services are also focusing on eco-friendly solutions. Use of biodegradable fluids, efficient recycling of hydraulic components, and minimizing fluid spill incidents are key efforts. Companies are beginning to prioritize sustainability in hydraulic designs and strategies, meeting both regulatory requirements and customer expectations.

The Impact of Automation

Automation is reshaping many aspects of hydraulic operations. With advancements in robotics and automation technology, mobile hydraulic services may evolve to incorporate automated systems for diagnostics and repairs. This can enhance accuracy and efficiency while reducing labor costs. As automation continues to grow, technicians will need to adapt and enhance their skill sets to incorporate these advanced systems into mobile services.

FAQs About Mobile Hydraulic Services

1. What types of machines benefit from mobile hydraulic services?

Mobile hydraulic services benefit heavy machinery, agricultural equipment, and industrial machines that utilize hydraulic systems, ensuring they remain operational with minimal downtime.

2. How can I find a reliable mobile hydraulic service provider?

Research local companies, read customer reviews, and evaluate their experience in servicing specific equipment to find a reliable provider of mobile hydraulic services.

3. What are common signs of hydraulic system failure?

Common signs include unusual noises, fluid leaks, slow operation, and inconsistent performance, indicating the need for mobile hydraulic services to address issues.

4. How often should hydraulic systems be maintained?

Hydraulic systems should ideally undergo maintenance every six months, or more frequently based on usage patterns and operational demands.

5. Can mobile hydraulic services help with hydraulic fluid changes?

Yes, mobile hydraulic services can facilitate hydraulic fluid changes, ensuring that the system runs efficiently and prolongs the lifespan of hydraulic components.